Central Heating New Zealand has a longstanding commitment to providing exceptional service. For over 20 years, we've offered comprehensive engineering services for project quotes, including precise heat load calculations, detailed system schematics, and clear wiring diagrams. Each year, we provide designs for approximately 1000 projects, consuming around 6,000 hours of our dedicated engineering team's time.

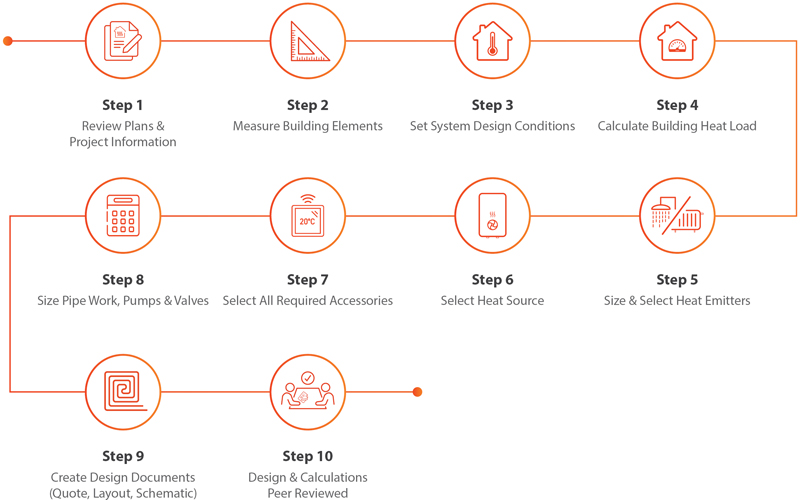

While many of our customers are familiar with the services we offer, the depth of our commitment to ensuring well-considered and accurate designs is often not fully appreciated. Our engineering team follows a meticulous 10-step process for each design completed. This process is continuously evolving to enhance effectiveness and adapt to new products and building requirements, yet its core functions remain consistent. This rigorous approach, while potentially leading to longer wait times, guarantees a high level of accuracy, preventing surprises for both installers and homeowners due to missing equipment or poor system performance.

Our 10-Step Process

Step 1:

Our initial step involves a careful study of all the provided information. We focus on two key areas:

- System Request and Client Requirements: Our sales team completes a "Design Request" form, providing our engineers with a clear understanding of the system's requirements. This includes client needs, preferred heat source, heat emitters, control requirements, and cooling needs.

- Suitability of Plans: We review the plans to confirm that all necessary information is available for accurate heat loss calculations. Typically, this requires floor plans, elevations, section views, and specifications for insulation and claddings. In situations where less information or no plans are available, we can still produce a heat load by utilising our "Design Information Form," which captures critical building details.

Step 2:

Using specialised software, we precisely scale and take measurements directly from the PDF plans. We measure the area of walls, ceilings, floors, and windows, inputting these measurements into our system design tool for accurate calculations.

Step 3:

Based on the design request and the home's location, we select the appropriate internal and external design conditions. These are typical conditions derived from:

- External Design Temperatures: We regularly update external design temperatures for each region using data collected by NIWA. For each project, we select the closest available recording point (from 142 nationally) and typically use the published 2.5% heating design figure (the temperature at which it will only be cooler for approximately 220 hours/year on average).

- Internal Design Temperatures: We adhere to standard internal design temperatures:

a. Living & Bathroom Heating: 22°C for radiator systems, 21°C for underfloor systems.

b. Bedroom and Utility Area Heating: 18°C for radiator systems, 17°C for underfloor systems.

c. Cooling: 27°C for radiant cooling systems, 24°C for fan coil systems.

These precise external and internal design temperatures are then utilised for calculating the peak heating and cooling loads for the building.

Step 4:

With confirmed building measurements and design conditions, we set the specifications for insulation and glazing values. We then calculate the fabric heat losses and gains of the building under these conditions. Allowances for infiltration and ventilation loads are subsequently included to establish the peak heating and cooling requirements.

Step 5:

Once heating and cooling loads are established, we proceed to size and select the appropriate heating and cooling emitters. The sizing of these emitters is carefully chosen to match the specific loading for each space, with expert consideration given to the need for slight oversizing for rapid response or undersizing for specific comfort or efficiency goals.

Step 6:

With the heating and cooling emitters selected, we determine the peak loading required for the heating and cooling source. In addition to the peak emitter load, we account for factors such as system losses (e.g., heat loss or gains from feed pipes) and any additional margin necessary to ensure the system is responsive during peak load conditions.

Step 7:

Following the selection of the heat source and emitters, we choose the necessary system accessories. Options like hot water heating and the requirement for buffer tanks are selected to perfectly suit the chosen heat source.

Step 8:

Valves, pumps, and pipework are meticulously sized to ensure that the required flow rates can be efficiently achieved throughout the system. The overall volume of the system is calculated, and the expansion and water treatment requirements are confirmed to guarantee system longevity and performance.

Step 9:

With the design finalised, we proceed to select or create the system schematic, generate a comprehensive equipment take-off/quote, and produce the equipment layout plans to clearly show equipment locations and the extent of heating coverage.

Step 10:

Each project is classified from Type 1 to Type 4 based on the home's size and system complexity. Depending on this classification and the experience level of the engineer who completed the design, a thorough design review may be required. If a review is needed, all aspects from Step 1 to Step 9 are meticulously checked before the design is approved for delivery and sent to the salesperson for distribution to an installer. This ensures unparalleled accuracy and prevents any unexpected issues for the installer or homeowner.